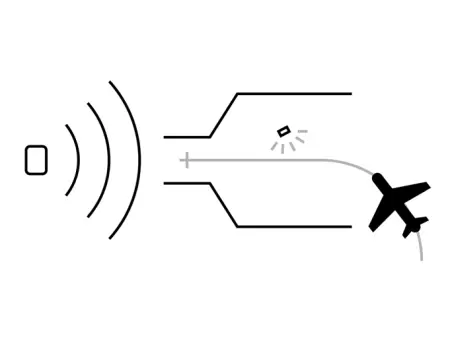

Even if the front of the aircraft is invisible or the lidar is placed on the side to the lead-in line.

TK Elevator

Airport Solutions

- Newsroom

- Contact

- Global website

-

Airport Solutions

Airport Solutions

back

SELECT YOUR COUNTRY / REGIONAmericas

Asia-Pacific

Europe

Middle East & Africa

Argentina

EspañolBrasil

PortuguêsChile

EspañolColombia

EspañolCosta Rica

EspañolEl Salvador

EspañolGuatemala

EspañolHonduras

EspañolMéxico

EspañolPanamá

EspañolParaguay

EspañolPerú

EspañolUruguay

EspañolUSA

EnglishAustralia

EnglishBangladesh

EnglishCambodia

EnglishIndia

EnglishIndonesia

EnglishMalaysia

EnglishNew Zealand

EnglishSingapore

EnglishThailand

EnglishČeská republika

češtinaDanmark

DanskDeutschland

DeutschEspaña

EspañolFrance

FrançaisHrvatska

HrvatskiItalia

ItalianoMagyarország

MagyarNederland

NederlandsNorge

NorskÖsterreich

DeutschPolska

PolskiePortugal

PortuguêsRomânia

RomânăSverige

SvenskaTürkiye

TürkçeUnited Kingdom

EnglishРоссия

Pусский